Written by

Joe J McLean

on 20/01/2018. Posted in

news

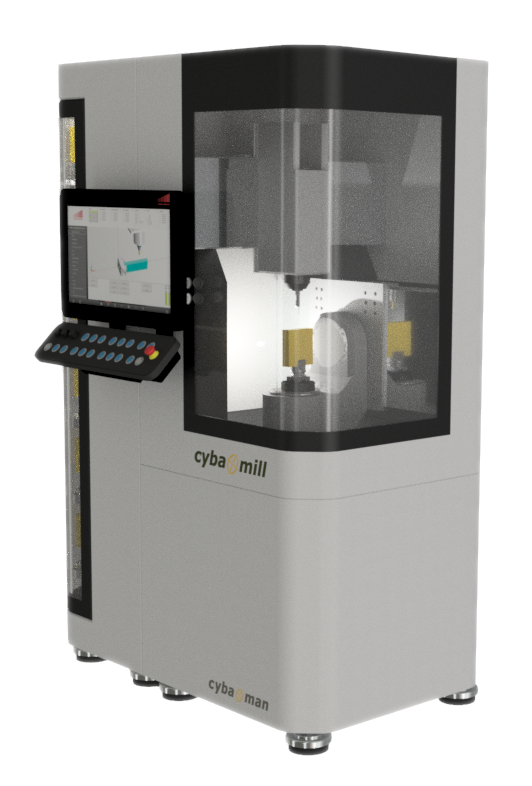

Cybaman Technologies have launched the new high-speed, high-accuracy milling machine on which the company will build the new product range.

After extensive consultation with existing customers significant improvements in machine specification, design and automation have been achieved to improve ma...

Written by

Joe J McLean

on 20/01/2018. Posted in

news

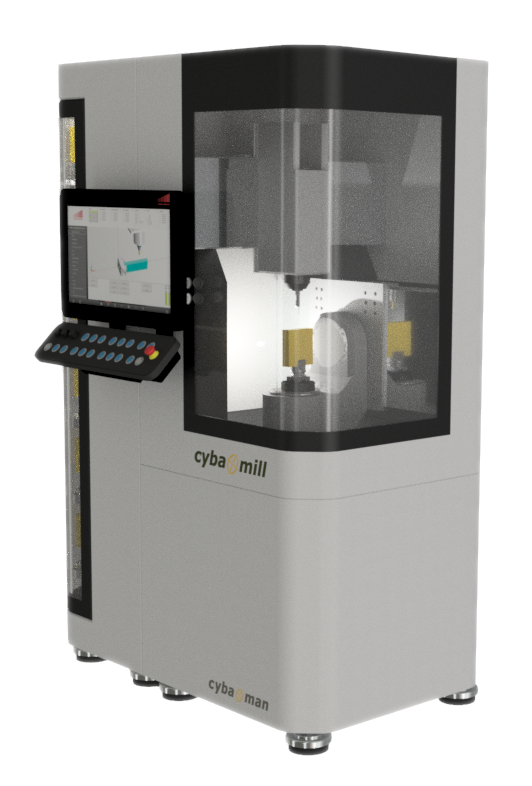

The UK’s Cybaman Technologies have launched its new Laser Metal Deposition system, based on the company’s Cybaman Digital Manufacturing Platform.

The company’s 6 & 5 Axis axis machine, originally designed as a high precision subtractive machining system, now has the capability to operate as an Addi...